Flat Roofing

C. Stevens Roofing offers three types of flat roofing depending upon the location and environmental conditions.

- Polyester

- EPDM Rubber

- GRP (Glass Reinforced Plastic)

Flat roofing is a specialty of C. Stevens Roofing, we can provide both premier and standard range products, if installed by ourselves we can offer 10,15 or 20 year linked guarantees which cover both materials and workmanship. We are currently expanding the area of Flat Roofing Services in response to high demand for this service throughout the Warwickshire region. We will provide, free of charge, an estimation and quotation service.

Polyester Flat Roofing

The most common system used by C. Stevens Roofing is polyester combining value, flexibility and a 12 year guarantee. NORDGUM is one of the most convenient solution for roofing and renovation works and waterproofing details. Good values of mechanical resistance thanks to the non woven polyester carrier and excellent low temperature flexibility permit to use it in difficult climate conditions at economic rates.

Waterproofing membrane made of Polymer elastomer modified bitumen (SBS) and reinforced with a non woven polyester carrier. The compound is a mixture of distilled bitumen and thermoplastic rubber which is Styrene Butadiene Styrene (SBS). The bottom surface is covered by a poliethilene burn off film.

Two finishes are available:

- NORDGUM (plain) available in 3mm, 4mm and 5 mm thickness or 4 Kg/m2 and with upper surface covered with sand or poliethilene burn off film on request.

- NORDGUM MINERAL available in 4 Kg/m2 and 4,5 Kg/m2, with upper surface covered by natural slate granules in order to protect the membrane against U.V. radiations.

Uses and Application

NORDGUM is one of the most convenient solutions for roofing renovation work and general waterproofing. Nordgum achieves good values of mechanical resistance thanks to the non woven polyester carrier and excellent low temperature flexibility that permit it to be used in difficult climatatic conditions.

The high degree of elasticity and flexibility allow the use in conjunction with elastomeric and polymer plastomer modified membranes which are reinforced with non woven polyester fabric, and the use as complementary layer in a two layer waterpoofing system.

Membranes are particularly well suited for the waterproofing of structures which may be subjected to limited movement or dimensional changes such as: -

- Flat, sloping and pitched roofs

- Site cast reinforced concrete

- prefabricated concrete

- Masonry cement

- Metal and laminated wood deck terraces

- Foundations

- Antiseismic foundations

- Car parks

- Tunnels

Applications instructions: The application of the membrane is by torch bonding using a suitable propane gas torch. Other tools include a knife and a trowel with a rounded end. Depending on the structure and the specification the membrane may be partial or spot bonded, loose laid or fully bonded.

When deciding on the system to use refer to our Specifier's Guide leaflets. The membrane should be applied to the substrate using a propane gas torch; this is used to burn off the burn-off film and melt a thin layer of bitumen while unrolling and laying the membrane. For a "spot bonding" installation, apply the flame only to those areas of the sheet to be bonded to the substrate making sure that the bonded areas are evenly distributed.

All membranes must be laid to allow side laps of 80 mm and end laps of 150 mm. If the membrane is only partially bonded remembel; that'll bonding must always take place for 1 meter each side of the end laps. Finally, SBS modified bitumen membranes can be used as exposed cap sheets only if the membrane ifr self- protected by mineral slate granules.

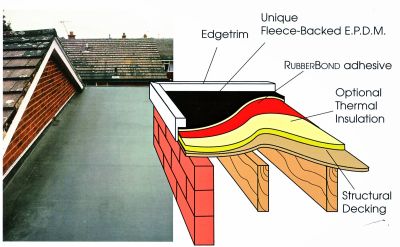

EPDM Flat Roofing

Durability assessments of roofing membranes found EPDM as the only membrane with no reduction in flexural fatigue resistance for all tests/locations, It would take over 50 years for EPDM to drop below 200 elongation, the MRCA ME-20 performance requirements for aged sheeting.

The greatest test of any construction material is how it performs under field conditions. The first membranes laid in the 1960's are still protecting flat roofs some 40 years later with over One billion square metres installed worldwide on Commercial and Industrial buildings including Offices, Schools, Hotels.

History of EDPM

RUBBERBOND FleeceBack is manufactured by Carlisle-Syntec USA who pioneered EPDM roofing membranes some 40 years ago. This material has established a record of superior product durability and long-term weather resistance.

The greatest test of any construction material is how it performs under field conditions. The first membranes laid in the 1960's are still protecting flat roofs some 40 years later with over One billion square metres installed worldwide on Commercial and Industrial buildings including Offices, Schools, Hotels.

Durabiiity assessments of roofing membranes found EPDM as the only membrane with no reduction in flexural fatigue resistance for all tests/locations, It would take over 50 years for EPDM to drop below 200 elongation, the MRCA ME-20 performance requirements for aged sheeting.

One of the most unique attributes is its ability to handle future roof alterations, unparalleled in the roofing industry, Unlike other roofing systems that degrade or become brittle over time, our membrane maintains its integrity and flexibility allowing future modifications to be made with ease.

What is EDPM

Ethylene Propylene Diene Monomer synthetic sheet rubber membrane is a remarkable material that:

- Repels all moisture, snow and rain

- Is flexible and easily bends with no stress, to follow the contours of the roof, upstands to walls, check curb edges, skylights, pipes, terminations into gutters and the like

- Can stretch with up to 300% elongation, which easily accommodates building movement

- Is not affected by extremes of temperature

- Will not tear, split or crack with age

- Is manufactured in large sheet sizes from 3.05 to metres wide and up to 30.5 metres long

Frequently Asked Questions

Is EPDM Expensive?

No, despite its considerable technical advantages it compares well with other quality roofing systems and because of its long life span can work out to be much cheaper over time.

Can I Walk on it?

Yes, it is designed for maintenance access, For heavy usage such as roof patio areas it can be overlaid with a variety of durable finishes, paving slabs, timber/plastic decking etc.

Is EPDM Environmentally Friendly?

RubberBond EPDM is an inert material with limited environmental impact during manufacture and use of the product.

Why Use EPDM?

Unlike other roofing systems that degrade or become brittle over time, our membrane maintains its integrity and flexibility throughout its life span.

Does EPDM Require Maintenance?

No, it does not require any systematic maintenance.

GRP Flat Roofing

GRP is a specifically modified high performance waterproofing system, designed to a provide a permanent solution to the problems usually associated with bitumen based coatings. For example cracking and blistering of the surface caused by the effects of sunlight which can result in failure of the roof within a few years.

GRP more commonly referred to as "glass fibre" is formed in situ by reinforcing polyester resin, which has been cured or hardened using a peroxide based catalyst with an emulsion bound chop strand mat. Once cured this forms a joint free laminate that will outlast virtually any other traditional roofing material..

Glass Reinforced Plastic

GRP is a specifically modified high performance waterproofing system, designed to a provide a permanent solution to the problems usually associated with bitumen based coatings. For example cracking and blistering of the surface caused by the effects of sunlight which can result in failure of the roof within a few years.

GRP more commonly referred to as "glassfibre" is formed in situ by reinforcing polyester resin, which has been cured or hardened using a peroxide based catalyst with an emulsion bound chop strand mat. Once cured this forms a joint free laminate that will outlast virtually any other traditional roofing material.

GRP Advantages

Glass Reinforced Plastic roofing has many advantages :

- 20 Year Guarantee

- Cold Applied and Cured

- Maintenance Free

- BAA Acredited

- Fire Retardent

- Lightweight

GRP roofing is a cold applied system that is ideally suited to both simple and complex structural designs and can be rapidly applied and cured to prevent water ingress giving total protection. The weld free design gives a continuous high performance covering. Available in a range of colours to suit the project, ideal for balconies, walkways, gutters and valleys and any domestic roof. The finish can simulate lead or other traditional finishes.

High performance is achieved as the GRP is made up of a combination of modified polyester base resins, emulsion bound chop strand mat and a finishing coat of pre-pigmented topcoat. When cured GRP is guaranteed to provide performance beyond that of more traditional bitumen or polymer based waterproofing coatings.

GRP Applications

GRP systems have been used successfully for over 20 years. They are fast becoming the preferred choice of Architects, Specifiers and Local Authorities. Installed by highly skilled and suitably trained installers, clients can be assured that GRP will continue to perform long after more traditional coatings have failed.

Every waterproofing application is formed entirely using GRP (Glass reinforced Polyester) guaranteeing no variation in rates of thermal expansion within the laminate. Being cold applied it can be easily installed to any shape or form and to close even the most complicated detail.

Thousands of square metres of specifically modified GRP waterproofing coatings are chosen every year with confidence, by discerning customers. A system complete with a comprehensive guarantee, which can be insurance backed if required. A system that has undergone extensive testing and is only installed by trained professionals.

The flexibility of GRP allows unusual shapes to be covered with ease and the GRP system can successfully be adapted for application to pitched roofs and vertical walls. The smooth tough surface can with-stand light foot traffic and may be upgraded at the time of application for use on balconies.

Work Guarantee

All work undertaken by C. Stevens Roofing is covered by clear, written guarantees including workmanship and material, to give you added confidence. Our guarantee is backed by a long established reputation in the business and is respected and valued by works professionals throughout the county.

Insurance Gaurantee

HomePro Insurance Backed Guarantees helping you to protect your investment. Although home improvement is one of the safest forms of financial investment, there is one pitfall that can be overlooked.

Most contractors issue a guarantee for the work they have undertaken, we are no different. However, thousands of contractors cease to trade each year.

If your chosen contractor ceased to trade HomePro will match the terms of the contractors original guarantee.